Installation of industrial floors

What are industrial floors?

How are industrial floors made?

Shake hardener for industrial floors

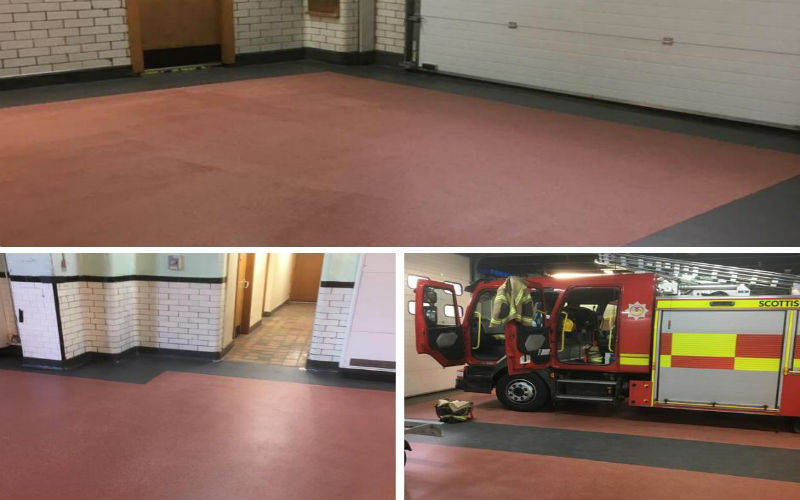

Industrial resin floors for garages

Industrial floors for food production

To the question - what is an industrial floor?

What should be an industrial floor?

Perform an industrial floor installation at a car wash.

A common human association is the floor in an industrial building.

That this is a large facility, with production characteristics and equipment.

Polyurethane epoxy self-leveling floors

But this does not mean that the industrial floor is used only at industrial construction sites.

The term “ industrial floor ”, to a greater extent, does not mean that the floor is located at an industrial enterprise - in a production room, warehouse, etc., but that the floor is operated under intense or extreme loads - “industrial” way.

Polyurethane concrete floors

New, capital construction or renovation, includes all branches of construction and is divided into industrial, civil, private, military, logistics, agricultural, etc.

Industrial construction is very different from civil construction.

When implementing such structures, modern technologies are used, operational loads are taken into account, the floors must meet all the requirements of technological processes, ensure a long and safe service life, and cost-effective operation.

Polyurethane coating install

Industrial floors include floors: for production workshops and premises, warehouses, garages, administrative offices, shopping and entertainment and exhibition centers.

For consumer services, educational and medical institutions, and residential buildings.

Floors on landings, on pedestrian areas inside and outside the premises are industrial floors , as they are subjected to strong abrasion loads, and, accordingly, must have high physical and mechanical characteristics of the industrial floor.

Simply put, the floors in a parking lot, in a garage, in a car park, in a hangar or a granary, are industrial.

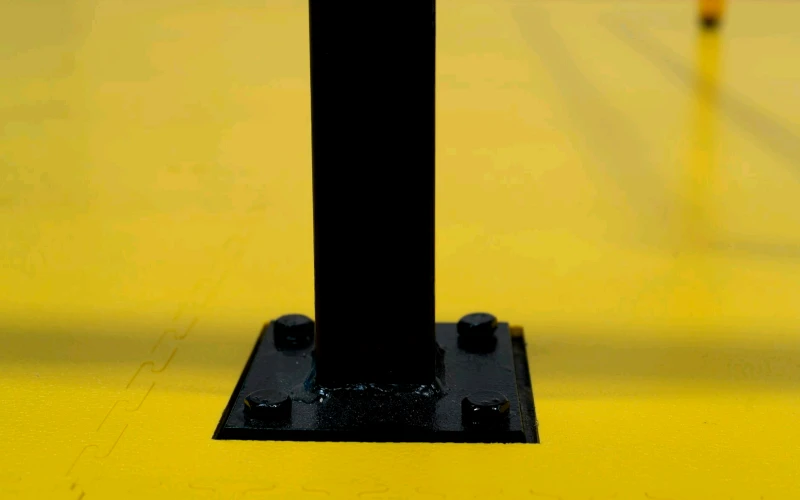

Industrial floors are widely used in logistics construction, they are used in the open air - these are airports, open parking lots, sites, construction of roads, tunnels, bridges, subways, sea and river berths.

Transport construction includes stations, depots and other transport buildings.

Epoxy floors

Of course, a floor that is subjected to certain mechanical and chemical influences, of course, must meet a given set of operating characteristics.

In modern construction, floors meet many requirements, floors must fulfill a variety of performance characteristics, from traditional ones: dust removal, wear resistance, chemical resistance to aggressive substances, high environmental friendliness;

Up to specialized requirements: anti-slip, non-sparking, anti-static, high purity, antibacterial, temperature resistance, weather resistance, use in a wide temperature range, and many others.

Polymer flooring

Civil housing construction is a branch of capital construction, the construction of which is residential and public facilities.

Public buildings intended for the temporary stay of people include a whole range of structures: trade enterprises, cultural and educational, health facilities, research and design, educational buildings, public utilities, residential buildings.

The floor is a structural part of the structure, it perceives dynamic, various operational loads.

The use of industrial floors in housing construction fully complies with all modern requirements.

Polyurethane sports flooring

By 2020, the term industrial floor has taken on a broader, more universal meaning.

When designing buildings and various structures for a specific purpose, all types of operation and loads must be taken into account in accordance with international standards.

At sites where the high characteristics of floors play a significant role, it is the industrial floor that is used .

Installation of industrial floors, with various types of finish coating, for all types of construction, buildings and structures

Varieties of industrial floors

Consider the popular systems of industrial floors.

Concrete industrial floors

Installation of concrete industrial floors

Industrial concrete floor system

-

These are durable floors consisting of M250-M400 concrete.

-

With a certain class of frost resistance (F) and water resistance (W).

-

Reinforcement of industrial concrete floor: steel, basalt, polypropylene fiber , steel mesh, reinforcing cage.

-

Acceptance, laying and grouting of concrete with trowels. Disc and blades.

- Concrete care : moisturizing, covering with a membraine, applying a membrane former, liquid hardener.

Advantages

-

The simplest version of the industrial floor, with its positive qualities and disadvantages.

-

Concrete flat floor, with good strength characteristics.

- Economical, at the beginning of operation.

Flaws

-

Over time, the floor begins to dust, the top layer of concrete wears out, to rubble. The effect of "peeling".

-

The occurrence of chips, shells, cracks.

- With such a condition of the coating, the undercarriage of the loaders wears out, floor maintenance increases in monetary terms (chemistry, repairs, man-hours, damage to the presentation of goods in the warehouse, damage to equipment.).

PS: after 28 days, this floor can be prepared for polymer coating, obtaining a seamless polymer floor with high chemical resistance characteristics.

Concrete floor installation

Industrial marble floors

Industrial marble chips are a popular choice for commercial and industrial applications. They have a number of advantages and disadvantages that should be considered when choosing this type of floor.

Benefits of marble flooring:

-

Durability and wear resistance: marble chips floors are very durable and resistant to mechanical damage, including impacts, scratches and stains.

-

Easy care: they are easy to wash and clean, and are resistant to stains and dirt.

-

Aesthetic appearance: marble chips are available in various colors and shades, allowing you to create unique and beautiful floor designs.

-

Anti-static properties: Marble chips have anti-static properties, which helps to prevent the accumulation of electrostatic charge and reduce the risk of fire.

-

Water Resistant: Marble chips do not absorb water or break down when exposed to moisture, making these floors suitable for use in wet conditions.

Disadvantages of marble chips floors:

-

High cost: Marble chips usually cost more than other types of industrial flooring.

-

Slipperiness: Marble chip floors can be slippery, especially if damp or wet. This may pose a danger to people walking on such a floor.

-

The need for regular maintenance: To maintain the beauty and strength of the marble chip floor, it must be cleaned and maintained regularly.

-

Demanding to install: Marble chip floors require experienced professionals to install and can be more difficult to install than other types of floors.

-

Possibility of cracking: during operation, marble chips floors can be subjected to loads, which can lead to cracks in the material.

Industrial floors from a marble crumb for car service

Shake hardener for industrial floors

Topping concrete floors | Dry shake toppings

Concrete floor, with hardening of the top layer, mineral hardeners, cement-based

Characteristics of an industrial floor with a topping

-

Wear resistance.

-

Waterproof.

-

Compressive strength.

-

Abrasion resistance.

- Color: grey. Color under the order.

Topping for industrial floors

Benefits of topping floors

The most economical option for money, with hardening of the top layer of the industrial floor.

Topping application | Dry shake toppings

The material is applied to fresh concrete, followed by mechanical grouting, to a gloss state.

After 7-21 days, put into operation.

Flaws

Low chemical resistance of the floor, poor resistance to highly aggressive environments.

Industrial floor for warehouse

Installation of polymer floors

Epoxy floors

Polyurethane floors

Industrial polymer floors for food production

Bulk polymer floors for a warehouse

Polymer floors - what is it?

The term "polymer floors", in its essence, characterizes what the finishing layer consists of, on a solid concrete base.

-

At the heart of the polymer flooring system , there is always a concrete slab with certain physical and mechanical characteristics, on which, subsequently, polymer bulk coatings are laid, in the form of mixed resins.

-

Polymeric or bulk industrial floors, consist of resins and hardeners.

-

Water based or solvent based.

- After polymerization, they turn into a durable and effective thin-layer or thick-layer coating.

Polyurethane epoxy self-leveling floors for food production

Types of basic polymer coatings

Epoxy, polyurethane, polyurethane-cement, acrylic, MMA or methyl methacrylate, polyuria, etc.

Technical characteristics of polymer floors for all industries

|

Seamless industrial resin floors for industrial kitchens

|

|

Chemical -resistant industrial polymer floors for the chemical industry

|

|

Wear -resistant industrial polymer floors for a warehouse

|

|

Elastic industrial polymer floors for parking

|

|

Temperature resistant industrial resin flooring for a bakery

|

|

Frost -resistant industrial polymer floors for cold rooms

|

|

Waterproof Industrial Resin Flooring for Brewery

|

|

Eco -friendly industrial resin flooring for healthcare facilities

|

|

Impact Resistant Industrial Polymer Garage Flooring

|

|

Antibacterial industrial resin floors for the pharmaceutical industry

|

|

Antistatic polymer floors for the electrical industry

|

|

Design polymer floors for cafes, bars, restaurants

|

|

Layer thickness: 0.5-9mm

|

|

Repairable

|

Application method

-

Surface preparation: mechanical processing of concrete (milling, shot blasting, grinding).

-

Dust removal, repair of concrete base from cracks, sinks, potholes.

-

Primer application (often with a powder of quartz sand, for better adhesion of subsequent resins).

-

Application in a bulk way, the base carrier layer, of various thicknesses.

- Applying protective varnish.

Flaws

-

Perhaps a high price per square meter, but it's all relative.

-

The service life of polymer floors is more than 10 years, of course, depending on the loads and operation.

-

If you want to drive around the parking lot on a caterpillar tractor, and the coating is intended for car tires, then no polymer coating will withstand.

- The system of industrial polymer floors is always individually selected for your project.

Polymer flooring

Industrial pvc floor tiles

Industrial PVC floor tiles have several advantages and disadvantages that may influence their choice depending on the specific situation and needs.

Advantages of industrial pvc floor tiles:

-

Durability : PVC tiles are made from durable materials that won't break or crack as easily as other types of flooring.

-

Moisture resistance : PVC tiles do not absorb moisture, making them ideal for wet areas such as bathrooms, kitchens and laundries.

-

Ease of Installation : PVC tiles are easy to install and require no special skills or tools to install. Moreover, it is easily cut and adapts to any shape of the room.

-

Variety of Designs : There is a wide range of designs and colors to choose from to suit your space.

Industrial PVC tiles for warehouse

Disadvantages of industrial PVC floor tiles:

-

High Temperature Instability : PVC tiles can warp at high temperatures, such as those that can occur when in contact with hot objects.

-

Discoloration : PVC tiles may turn yellow with prolonged exposure to UV rays, so do not use them in open sunny areas.

-

Softness : PVC tiles are softer than ceramic tiles or natural stone, which can cause scratches and scuffs from furniture or pets.

-

Light wear layer : In some cases, PVC coating may have a slight wear layer, so be careful with heavy furniture, wheels and other items that can leave marks on the surface.

-

Limited environmental friendliness : PVC tiles are not environmentally friendly as they are made from plastic, which is not biodegradable and can have harmful effects on the environment.

-

Installation : Installation of PVC tiles requires a smooth and even surface so that the tiles lie easily and there are no gaps between the tiles. If the base is not level, it must be prepared, which can increase installation time and cost.

-

Adhesive Use : When installing PVC tiles, an adhesive is usually used, which can contain toxic substances and can take up to 24 hours to dry completely.

Industrial pvc tile for cafe

Polished concrete floor

Polished concrete floor

Strengthening and dedusting concrete floors

What is polished concrete?

Polished concrete is a concrete floor of a certain brand, which, after 28 days of maturation, can be mechanically processed, with the application of liquid hardeners.

Specifications of Polished Industrial Floors

|

Waterproof industrial floors

|

|

No dust on industrial polished floors

|

|

Wear -resistant polished industrial floors

|

|

The absence of top layers (no peeling and peeling of the coating)

|

|

Eco -friendly industrial polished floors (green impregnation technologies)

|

|

Oil resistance of polished industrial floors

|

|

Design Solutions for Industrial Polished Floors

|

|

Color range in industrial polished floors

|

Polished concrete floors

Polished concrete floors

-

Grinding.

-

Polishing.

- Application of liquid hardeners.

Flaws

-

The high price per square meter, again, everything is relative.

-

Low quality of concrete in Ukraine.

-

A strong corrosive liquid medium that can destroy a polished concrete floor if it penetrates the concrete body.

- Rigid coating, the possibility of cracking.

Advantages

-

The absence of top layers that can peel off during the operation of industrial floors.

-

The concrete floor itself is a complete and monolithic system.

-

Liquid hardener, penetrates into the top layer of concrete, closes micropores, thereby contributing to the compaction of the top layer of the floor and the absence of dust.

-

The ability to achieve gloss and mirroring by polishing.

- The possibility of obtaining a design effect, when opening the top layer of concrete to the filler (crushed stone), having received the effect of "marble chips".

Dedusting concrete floor

These four types of industrial floors are one of the main systems in industrial floors in Ukraine.

Of course, there are other coatings, such as: self-leveling cement systems, pvc flooring, ceramic plates or rubber plates for industrial floors, but their use is not so massive, although we will also talk about them in our next reviews.