Floor waterproofing

Car wash floors

Resin floor for car wash

Polymer floors for car service

The install of polymer floors

Epoxy floors

Real Project

Project Data

-

G. Kotovsk, Ukraine.

-

Object: car wash of trucks.

-

Base: waterproof industrial floor.

Epoxy floor installation

A task

-

It is necessary to waterproof the floor with a wear-resistant material.

- It is required to create a finishing, chemical-resistant coating and protect the concrete floor from water, oil, detergents.

Solution

The decision was made to apply VIMEPOX TOP-COAT polymeric epoxy top coat.

VIMEPOX TOP-COAT is a two-component, colored, solvent-free epoxy compound.

Properties VIMEPOX TOP-COAT

-

High mechanical strength: hardness combined with relative elasticity and abrasion resistance.

-

Waterproofing and chemical resistance to exposure to: acids, alkalis, solvents, fuels and lubricants, sea water and detergents.

- Durable, no weather damage.

Application

-

VIMEPOX TOP-COAT is used as a protective coating and decorative painting of cement-concrete structures, screeds, as well as for plastered, asbestos-cement, vertical and horizontal metal and steel surfaces.

-

VIMEPOX TOP-COAT is designed for sealing (painting) surfaces less than 1mm thick (for repeated painting), which complies with the DIN 28052-1 standard for medium mechanical, static and kinetic effects (for example, for cars with inflatable tires) 2 categories with load up to 1 N/mm2 = 100 t/m2.

-

VIMEPOX TOP-COAT has excellent chemical resistance.

-

The top layer of coatings painted with this material does not show any toxicity, as well as the effect of transferring harmful substances to food.

- This epoxy composition is suitable for floor and wall covering, for premises intended for food production.

Thin layer epoxy floor

Foundation Requirements

|

The basis for the application of polymer waterproofing |

1. The substrate must be solid, clean, free of dust, rust and oil stains, which will promote adhesion of the epoxy. 2. Preliminarily, the base must be processed mechanically - shot blasting, sandblasting and grinding, followed by removal of dust and dirt with a powerful industrial vacuum cleaner. |

|

Foundation strength |

≥ 1.5 N/mm2

|

|

Substrate moisture |

≤4%

|

|

Grade concrete |

Not less than C 20/25

|

|

The quality of the cement screed |

Cement content ≥ 350 kg/m3

|

|

Age of the cement-concrete base |

> 28 days

|

|

No wet environment |

1. The epoxy coating process should not take place in a humid environment and especially in the presence of water vapor. 2. Vapors will adversely affect the adhesion of the material, and will contribute to its further delamination from the substrate. 3. It is necessary to foresee the existence of such conditions in advance. |

Stages of work

Foundation preparation

-

The concrete base was mechanically processed using a grinding machine.

-

Eliminated laitance, which is a weak point in the concrete floor.

-

The cracks in the concrete floor were repaired with repair mortars with a quick set of strength.

-

Created a dense and partially rough base to increase the adhesion of the polymer coating.

- The surface was cleaned from dust and pollution, using an industrial forest cleaner.

Mechanical preparation of concrete floors

Self-leveling floor for car wash

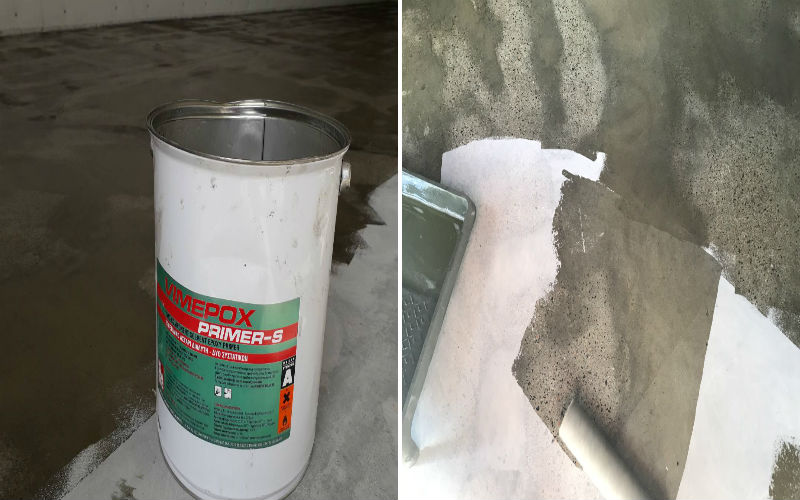

Padding

-

Application of VIMEPOX Primer- S, on a concrete base using a roller.

- Consumption: 0.15-0.3 kg/m/sq.

VIMEPOX PRIMER-S is a colorless, solvent-based, two-component epoxy.

-

It has high hardness and abrasion resistance.

-

Resistant to water, acids, alkalis, oil products.

-

Classified as SR-B2.0 according to EN 13813.

-

VIMEPOX PRIMER-S is used to seal the surface of concrete and cement substrates before applying VIMEPOX FLOORING and VIMEPOX TOP-COAT epoxy compounds or VIMEPOX COAT and VIMEPOX SP-COAT epoxy paints.

- After application, it dries quickly, which allows you to apply the main material in a short time.

Application

-

VIMEPOX PRIMER-S is recommended for outdoor use on old or new porous substrates that will subsequently be painted with VIMEPOX FLOORING and VIMEPOX TOP-COAT epoxy compounds or VIMEPOX COAT and VIMEPOX SP-COAT epoxy paints.

- In this case, the base can be plaster, cement screed, concrete or brick.

Dedusting concrete floor

Application of waterproofing top coat VIMEPOX TOP-COAT

-

After 24 hours, the first layer of epoxy was applied, at a rate of 0.6 kg/m/sq.

-

After 24 hours, a final coat of epoxy was applied, at a rate of 0.6 kg/m/sq.

-

Total dry film thickness: 1-1.5 mm.

- The epoxy coating is spread over the surface with a spatula and a roller, with the obligatory rolling with a spiked roller.

Epoxy industrial floors

Base Care

-

The floor dried within 7 days, without drafts.

- After 10 days, was put into operation.

The advantage of polymer thin-layer waterproofing

-

Wear resistance.

-

Chemical resistance.

-

Waterproof.

- Color scale at the request of the customer.

Polymer flooring