Needle Punched Non Woven Geotextile

Thermally fixed geotextile

Thermally bonded geotextile

What is geotextile for?

What is geotextile?

What is geotextile?

How is geotextile applied?

Needle punched geotextile.

Thermally fixed geotextile.

What is geotextile made of?

Polypropylene Geotextile.

Fields of application of geotextile materials.

Density of geotextile and its purpose.

Recently, in human life, geosynthetic materials have been widely used.

One of the multifunctional and effective is geotextile.

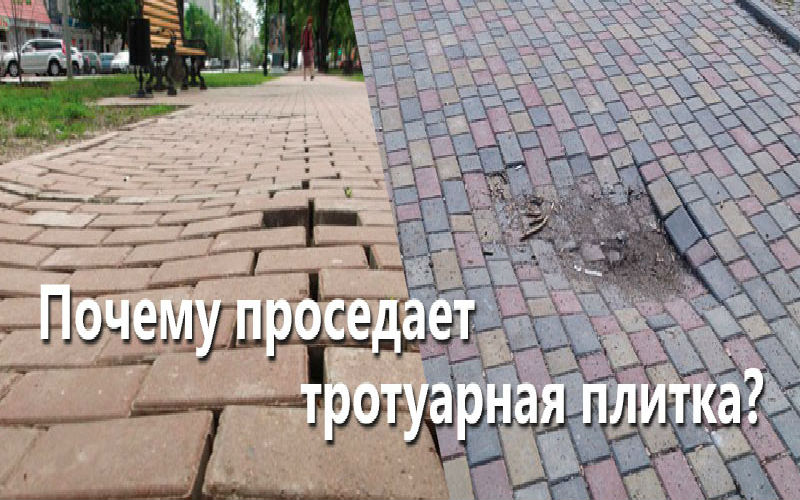

If you laid paving slabs, and after a year pits formed due to soil shrinkage.

Shrinkage of paving slabs

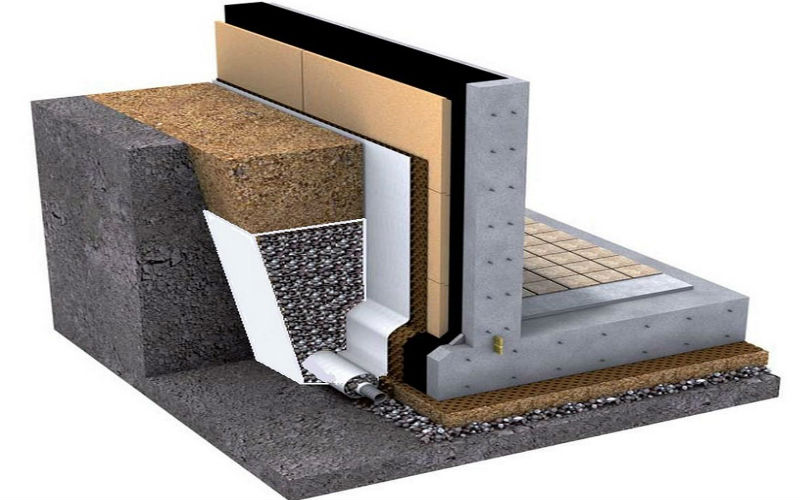

If you need to divert water from a structure or site, use drainage, as well as protect the waterproofing of the foundation from damage.

Drainage system for wastewater

If you need to prevent the growth of weeds in the garden, and the fruits must be clean.

Geotextile for agriculture

Geotextiles will cope with all these tasks

What is geotextile?

-

Geotextile is a non-woven or woven fabric made from polypropylene or polyester.

-

Geotextiles are one of the types of geosynthetics designed to work with soils.

-

The use of geotextiles increases the strength and durability of building objects.

- Geotextile materials are easy to install and do not require the use of special equipment for laying and, importantly, allow you to save consumables.

How is geotextile applied?

Characteristics of geotextiles that can be used in our lives

Drainage

Сollects and organizes the removal of precipitation, groundwater or other liquids.

Geotextile for drainage

Filtration

Retains soil or other particles that are subject to hydrodynamic forces.

Slope reinforcement

Reinforcement

strengthening, hardening of foundations and waterproofing coatings.

Geotextile for bituminous waterproofing

Separation

Prevents mixing of materials with different fractions.

Geotextile for soil separation

-

Geotextile separates soils of different fractions, preventing their suffusion (mutual penetration).

-

For example, if a layer of crushed stone is poured over sandy loam or loam.

-

By separating them with a layer of geotextile, we will get a significant benefit in that the crushed stone will not settle into the loam, which will prevent the structure from settling.

- In addition, since there is no loss of crushed stone in the ground, the consumption of inert materials is reduced and rutting is reduced.

Protection

-

Prevents or limits mechanical damage to the protected material (waterproofing).

-

Geotextiles are highly resistant to punctures and bursting.

- Due to this, geosynthetics protect waterproofing geomembranes from damage and additionally strengthen the structure, as it perceives tensile forces.

Geotextile for moisture drainage

Strengthening and stabilization

-

Tensile stress is transferred to the geotextile from the overlying soil layers, as well as external loads.

- This improves the working conditions of the underlying soils of the base, due to the reduction of the vertical load due to its redistribution over a large area with geotextile material.

Geotextile for ground reinforcement

Types of geotextiles

Needle punched geotextiles

-

It is a non-woven fabric made of synthetic fibers.

-

Needle-punched geotextiles are produced by passing a mass of ready-made raw materials from very thin threads through a number of harpoon needles, which, punching through a mass of raw materials, tangle the threads together.

-

Needle-punched geotextile - does not rot, is not affected by insects and rodents, is resistant to thermal-oxidative aging, as well as high chemical resistance, significant elongation to break and uniformity of structure.

- Due to these properties, needle-punched geotextiles provide excellent performance, high damage resistance and excellent filtration properties.

Needle punched geotextiles

Needle punched geotextiles

Application of needle-punched geotextile

-

Road construction, roadway reinforcement.

-

Construction of hydraulic structures (protection of waterproofing membranes).

-

Organization of drainage systems.

-

Construction of tunnels, overpasses, railways.

-

When laying paving slabs in a "cementless" way.

-

In landscaping, to separate the layers of soil-sand-rubble, as well as to protect against unwanted growth of roots and weeds.

- When repairing a bituminous roof, as a reinforcing sheet.

Thermally fixed geotextile

-

They are made from polyester or polypropylene fibers, mechanically with further bonding using thermal exposure.

-

Thanks to this method of production, the fibers are melted and rigidly fastened together.

-

The material becomes tear-resistant, much stronger than needle-punched geotextiles.

- However, its filtering properties are somewhat reduced, since the filtration process occurs only in the transverse direction, but in general, this effect is not significant.

Thermally fixed geotextile

Thermally fixed geotextile

Features of physical and mechanical properties of thermofixed geotextile

-

High tensile strength.

-

Good water permeability.

-

Structure homogeneity.

-

High level of elasticity.

-

High elongation at break.

-

Resists alkalis, acids and other chemical compounds.

-

Does not rot throughout the entire period of operation.

- Does not decompose.

Application of heat-set geotextile

-

in landscape design.

-

For different types of roads, including sidewalks, footpaths.

-

For sewerage and drainage systems.

-

For sports fields and car parks.

-

For foundation and roofing (inverted, green).

- For embankments, beaches, reservoirs, for landscaping and land management.

What is geotextile made of?

The geotextile fabric is made from polypropylene, polyester, and also with the addition of cotton fibers.

What is the difference between the raw materials for the production of geotextiles?

Geotextile made of polypropylene yarns

-

Made from continuous monofilament (primary raw material).

-

It is produced both by the needle-punched method and by thermal bonding.

-

It has high filtering and draining properties, does not accumulate moisture inside.

-

Such textiles are characterized by white color.

-

Polypropylene Geotextile : A non-woven geotextile made from high tenacity UV stabilized polypropylene fibers.

- It is used for filtration, separation, protection, dehumidification and reinforcement.

Polypropylene Geotextile

Scope of application

-

Automobile and railway roads.

-

Areas of heavy traffic.

-

Landfills for solid and liquid waste.

-

Roofing and waterproofing.

-

Tunnel and underground works.

- Coastal protection.

Polyester Geotextile

-

Made from staple fiber mechanically (needle-punched), possibly with further heat setting.

- Such a geotextile fabric is used for separating layers, for arranging drainage, as well as for reinforcement.

Geotextiles made from cotton or wool fibers

-

Subject to decay.

-

The use of such geotextiles when working with soils is not advisable.

A unique feature of geotextiles is the combination of properties such as stiffness, porosity and elasticity.

This explains the wide application in the field of construction.

Fields of application of geotextile materials

Geosynthetics in road structures

-

To divide the roadway.

- For reinforcing the roadway.

Geotextile for road construction

Geosynthetics in the construction of drainage systems

-

Wall drainage.

- Reservoir drainage.

Geotextile for drainage

Geosynthetics in erosion control structures

-

Strengthening slopes.

- Strengthening embankments.

Geotextile for slope reinforcement

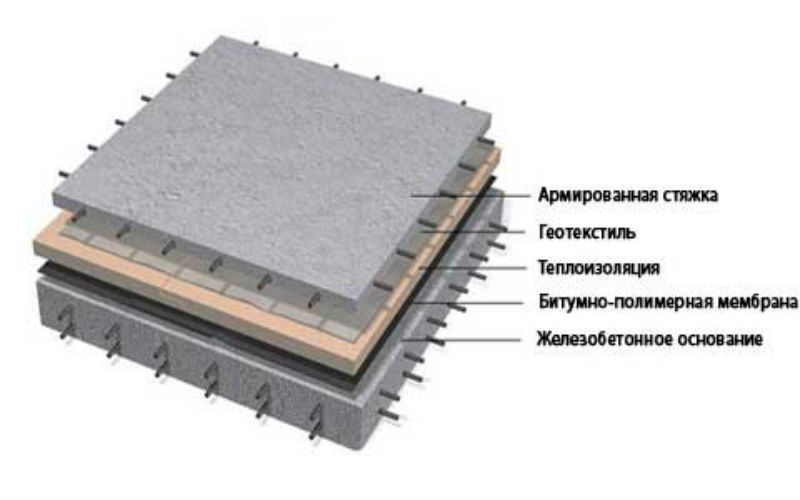

Geosynthetic materials for roofing

-

"Green" roofs.

- Operating roofs.

Geotextiles for green roofs

The use of geosynthetics when laying paving slabs

-

Geosynthetic material prevents mixing of soil layers, improves water drainage.

-

Eliminates shrinkage and formation of holes in a paving.

- Protects against weeds.

Geotextile for drainage

Geosynthetics in land management and construction of artificial reservoirs

-

Geosynthetic materials are actively used in landscape design.

-

Provide protection from weeds.

- Used in the construction of artificial reservoirs and pools.

Geotextiles for artificial reservoirs

Geosynthetics in crop production

-

Geosynthetics protect plants in winter and summer.

- Prevents the growth of weeds.

Geotextile for horticulture

Density of geotextile and its purpose

The main geotextile densities used in Ukraine are from 50 gr/sq.m. to 500 gr/sq.m.

When selecting the required density, it is necessary to take into account many factors and clearly understand what main functions the geotextile will perform in the structure.

-

To reinforce the coating, polypropylene, thermally bonded or thermofixed geotextiles are used.

-

For drainage and filtration, needle-punched geotextiles and thermofixed geotextiles are used.

- The higher the density, the lower the permeability.

Density 100g/sq.m. – 150g/sq.m

-

When arranging lawns and ornamental ponds to separate layers of sand-crushed stone-soil.

-

When organizing drainage systems (reservoir drainage).

- In landscape design to separate layers.

Density 150g/sq.m. – 200g/sq.m

-

Protection of waterproofing membranes.

-

Laying paving slabs to separate the layers of soil-sand-crushed stone.

- When organizing drainage systems (reservoir drainage).

Density 200g/m2 - 250g/m2

-

Paving slabs.

-

Construction of parking lots.

-

Construction of access roads.

-

To strengthen the slope.

- During the construction of artificial reservoirs, pools.

Density 250g/m2 - 300g/m2

-

Reinforcement of the roadway.

-

Strengthening embankments and slopes.

-

Swimming pool construction (protection of waterproofing membranes).

-

Construction of inversion roofs, exploited roofs.

- For reinforcing the base of an industrial floor.

Density over 300g/sq.m

-

During the construction of hydraulic structures.

-

Reinforcement of pavement bases.

- Railway construction.

What kind of geotextile can be bought in Ukraine?

In the Ukrainian market, geotextiles are represented by the following brands that have proven themselves in the best way.

-

TIPPTEX needle -punched geotextile.

-

K. Tex.

-

Geopulse.

-

Fleece.

-

fibertex.

-

Thermally bonded geotextile TyparSF.

-

Pulsar.

- SAN geo.

How to buy geotextiles in Ukraine and deliver to you?

The FLOORTOP company sells and delivers geotextiles throughout Ukraine.